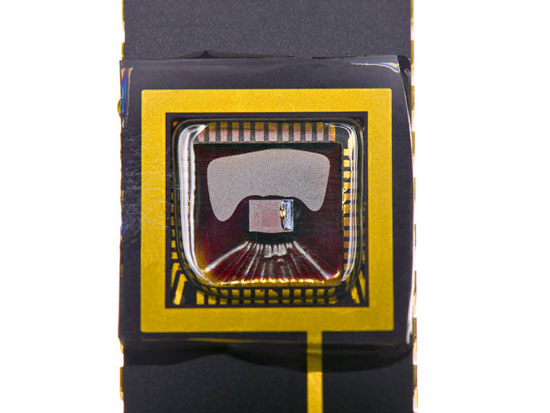

Strong performance: During tests, the organic sensors proved to be up to three times more sensitive to light than conventional CMOS sensors. Photo: A. Heddergott / TUM

Strong performance: During tests, the organic sensors proved to be up to three times more sensitive to light than conventional CMOS sensors. Photo: A. Heddergott / TUM

Researchers from Technische Universität München (TUM) have developed a new generation of image sensors that are more sensitive to light than the conventional silicon versions, with the added bonus of being simple and cheap to produce. They consist of electrically conductive plastics, which are sprayed on to the sensor surface in an ultra-thin layer. The chemical composition of the polymer spray coating can be altered so that even the invisible range of the light spectrum can be captured. This opens up interesting new development possibilities for low-cost infrared sensors aimed at compact cameras and smartphones (Nature Communications).

Many compact and cellphone cameras contain silicon-based image sensors produced using CMOS (complementary metal oxide semiconductor) technology. Prof. Paolo Lugli and Dr. Daniela Baierl from TUM have developed a cost-effective process to improve the performance of these CMOS sensors. Their approach revolves around an ultra-thin film made of organic compounds, in other words plastics.

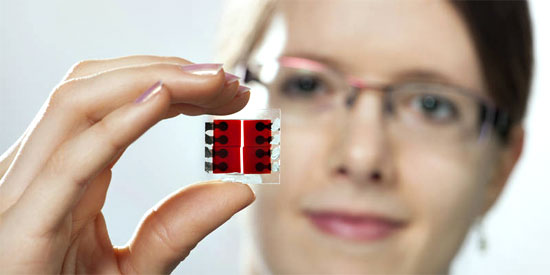

The challenge lay in applying the plastic solution to the surface of the image sensors. The researchers tested spin- and spray-coating methods to apply the plastic in its liquid, solution form as precisely and cost-effectively as possible. They were looking for a smooth plastic film that is no more than a few hundred nanometers thick. Spray-coating was found to be the best method, using either a simple spray gun or a spray robot.

Ultra-thin: Organic sensors can be applied to CMOS chips over large and small surfaces, as well as to glass or flexible plastic films. Photo: U. Benz / TUM

Ultra-thin: Organic sensors can be applied to CMOS chips over large and small surfaces, as well as to glass or flexible plastic films. Photo: U. Benz / TUM

Thin coating with high sensitivity to light

Organic sensors have already proven their worth in tests: They are up to three times more sensitive to light than conventional CMOS sensors, whose electronic components conceal some of the pixels, and therefore the photoactive silicon surface.

Organic sensors can be manufactured without the expensive post-processing step typically required for CMOS sensors, which involves for example applying micro-lenses to increase the amount of captured light. Every part of every single pixel, including the electronics, is sprayed with the liquid polymer solution, giving a surface that is 100 percent light-sensitive. The low noise and high frame rate properties of the organic sensors also make them a good fit for cameras.

Potential for developing low-cost infrared sensors

Another advantage of the plastic sensors is that different chemical compounds can be used to capture different parts of the light spectrum. For example, the PCBM and P3HT polymers are ideal for the detection of visible light. Other organic compounds, like squaraine dyes, are sensitive to light in the near-infrared region.

“By choosing the right organic compounds, we are able to develop new applications that were too costly up until now,” explains Prof. Paolo Lugli, who holds the Chair of Nanoelectronics at TUM. “The future uses of organic infrared sensors include driver assistance systems for night vision and regular compact and cellphone cameras. Yet, the lack of suitable polymers is the main hurdle.”

via – tum.de/nc/en/about-tum/news/press-releases/short/article/30292/

This is stunning, I was wondering these days how surprising can be the evolution. The answer came fast.